Track record

18 April 2022

For more than two decades, Omega Group has worked on designing, engineering and manufacturing one type of access equipment: the track-based scissor.

Despite tweaks and updates to models over the years, the company’s core focus remains the same today as it did then: scissors. Its current product lineup consists of five series of tracked scissors with platform heights ranging between 27 and 36 feet.

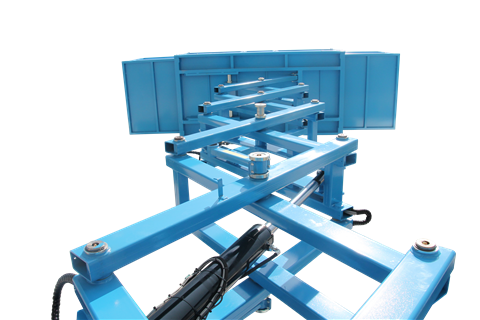

OMEGA 930TS. (Photo: Omega Group)

OMEGA 930TS. (Photo: Omega Group)

Omega’s dedication to produce only one type of product brings to mind the well-known quote from Heather Hart, “It’s better to do one thing well than 10 things poorly.”

But Arjan Roelse, co-founder of Omega, quickly strikes that down.

“It’s not that we don’t do anything else,” explains Roelse. “We have done some other projects in the past, including telescopic booms…”

However, as any successful business knows, diversification is of utmost importance – and that’s exactly what Omega has worked consistently on for the past decade and a half.

Back to basics

Founded by Leen Stehouwer and Roelse more than 20 years ago, The Netherlands-based company’s first few years of manufacturing were solely custom-built products based on clients’ needs and requests.

“Machines were designed and built to meet what the customer had in mind,” Roelse says. “Over time, this changed.”

Roelse explains that in some cases, the customer input was not feasible, and then they quickly found themselves straining to meet machine design regulations and requirements. “The needs and input of customers and having to comply with standards at the same time was causing difficulties,” he says.

The founders decided, in the best interest of the company, to move forward with specific models for the industry, which, in turn, eased up the challenges that came with custom-made orders. However, another bump in the road quickly materialized, and, again, Omega had to pivot.

Diversification

When the Great Recession hit in 2008, Omega also took a hit. Sales nearly came to a halt, and overall, business was extremely slow.

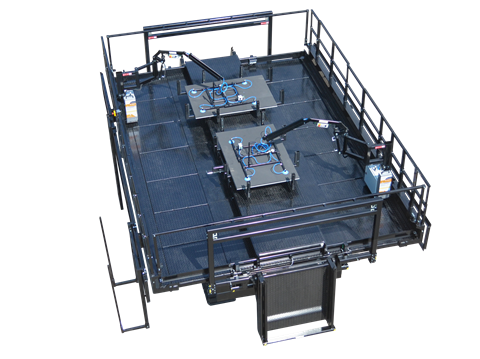

OMEGA 408TS. (Photo: Omega Group)

OMEGA 408TS. (Photo: Omega Group)

Roelse and Stehouwer knew in order to keep their company afloat, they needed to branch out, to think beyond product manufacturing.

“We knew we needed to tie ourselves with another activity, or market,” Roelse explains.

While its manufacturing focus was always at the forefront, Omega had quietly invested in two additional, minor divisions – one in rental and one in parts. The founders decided to grow these branches, and in 2012, the decision was made to split up the independent entities and offer wider solutions for the industry.

Thus, Omega Group became the parent of Omega Sales, Omega Rent, Omega Parts, Omega Service and Omega Solutions. These branches, although separate, work together for Omega, and have been the backbone of the company’s expansion and diversification over the last seven-plus years.

Building partnerships

One of the first big announcements came in 2014, when Omega Sales was named an authorized dealer for U.S.-based MEC Aerial Work Platform products throughout the Benelux region. Previously, Omega’s facilities had been used as a MEC distribution center for the central European region, but under the new agreement, Omega began offering parts, service and training support for MEC.

In the years following, Omega brought on Snorkel and Faresin telehandlers. Then, in 2015, the company did a 180 and announced the debut of two track-mounted telescopic boom lifts.

Today, Omega offers the following products: track-based scissors that include the 400TS, 600TS, 800TS, 900TS and 1200TS. (See box for product details,) and one truck-boom crane, the 2085TC. (And, for the record, the company does still custom-build products on request.)

Where they are and where they’re going

Roelse tells ALH that roughly 45 percent of the company’s machines are used within European greenhouses. The other 45 percent goes to rental. And the remaining 10 percent? Well, some of those have started to land on North American soil.

OMEGA 830TS. (Photo: Omega Group)

OMEGA 830TS. (Photo: Omega Group)

“One thing lead to another,” Roelse says of moving into the North American market. “A company in Canada a few years ago had heard about our equipment. They reached out to us – and it was a bit of a surprise.”

The Ontario-based customer told Roelse they were continually having issues with access equipment getting stuck in the mud; they wanted to try out Omega’s heavy-duty, track-driven units.

“They asked, ‘Can you provide them to us?’” Roelse says. “We were happy to do it, of course.”

What began as a temporary trial run eventually became a permanent solution – the machines never left Canadian soil – and they’ve been utilized on a variety of jobs, Roelse says.

Today, Omega’s Canadian distribution comes from Lakeshore Equipment Solutions, which takes care of all sales and support for that market. Furthermore, Omega has agreements with a network of independent service companies throughout the U.S. and Canada to help fulfill any equipment maintenance or needs.

When asked if Omega plans to attract more North American customers, and what their plan of attack for parts, sales and service would be, Roelse pauses.

“That’s a good question,” he says. “It’s a bit of a chicken and egg scenario.”

For Omega’s first units in Canada, there was a nearby company that serviced excavators and similar track-based construction equipment, so they formed a partnership and any maintenance or service was carried out by the local company. Following another order of Omega scissors, the Canadian company invested in their own technical department, but, Roelse notes, if the need for more expertise ever was an issue, “we would fly service guys to wherever they needed to be.”

Today’s market

OMEGA 612TS. (Photo: Omega Group)

OMEGA 612TS. (Photo: Omega Group)

As the industry continues to battle global supply chain issues, Omega is well-prepared to supply any customer’s parts of service needs, according to Roelse.

“We carry a significant stock, which is there for our sales and service needs,” he says. “But you never know what can happen and we do foresee some challenges.”

Roelse explains that while the company has enough parts and stock on-hand to produce machines for the next year or more, Omega does have orders out for engines and materials that will need to be delivered in a timely fashion. But, “for now, we are still ok,” he says.

When looking to the future, Roelse takes a moment to consider the past, including Covid-19’s impact on the industry as a whole.

“When Covid-19 started almost two years ago, I was under the assumption that the whole [access industry] would collapse,” he says. “But, the opposite happened.

“Everybody seems to be doing well, and the number of machines being sold is through the roof.”

Omega expects the coming year to be strong; the company has fielded a number of equipment orders and requests, with offers still coming in.

“We are a niche player,” Roelse admits. “We don’t build thousands of machines a year, so we aren’t worried too much if production drops a little.

“It’s one thing if you’re producing 1,000 machines a week and suddenly you’re only doing 500.”

In global terms, Roelse sees the market as a whole being “very positive” for 2022. However, he also cautions that industry hurdles could dampen the optimism.

“The question is, ‘Will the industry be able to supply the market quickly enough?” Roelse muses before providing his own answer:

“At the end of the day, if we are using a certain engine for our machines and that provider cannot supply those anymore, we will look toward other companies and suppliers. It’s an opportunity for other businesses.”

Machine specs and details400TS Series405TS

600TS Series612TS

800TS SERIES820TS

900TS SERIES920TS

1200TS SERIES1200TS

|

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM